Linoleum was invented by English rubber manufacturer Frederick Walton in 1861. From 1900 to 1950, it was extremely popular and could be found in almost every home in the U.S. But, after 1950, its popularity plummeted as more cost-effective, resilient flooring, such as vinyl tile, was invented. But, recently, with the rise of the green movement, linoleum is making a comeback. It should be noted, however, that linoleum is no longer manufactured in the U.S., with Armstrong dropping off as the last domestic manufacturer in 1947.

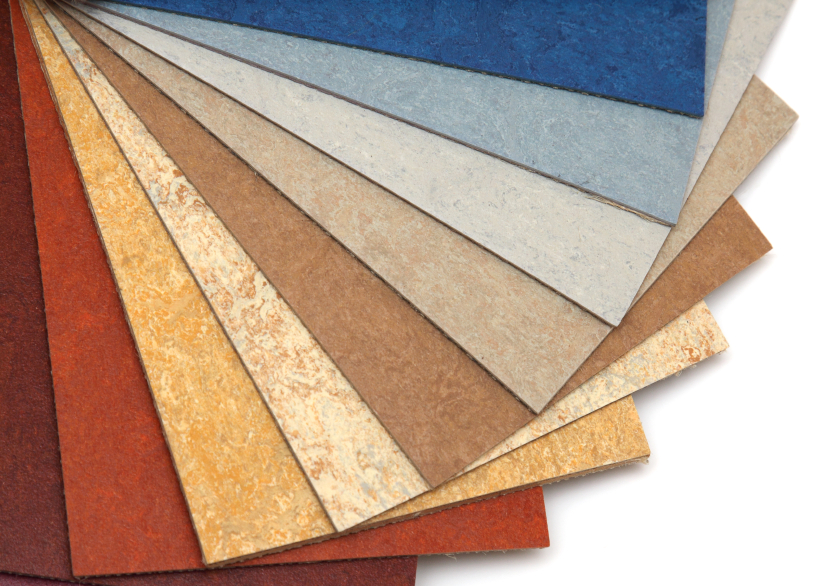

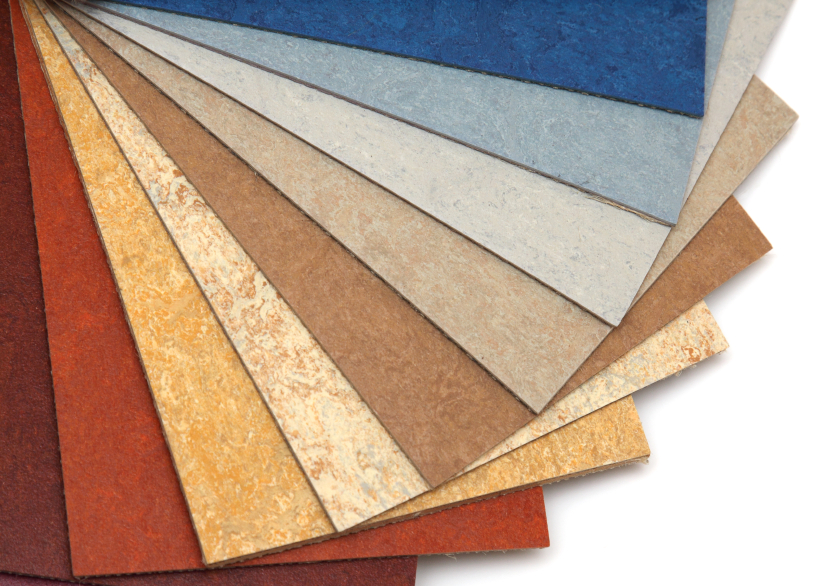

Linoleum composition

Linseed oil is the primary ingredient in linoleum. Other natural materials, like resins, limestone, powdered cork, wood powder, mineral pigments and jute fabric, make up the remaining ingredients. In fact, the name “linoleum” is derived from the Latin word for linseed,

linum, and the Latin word for oil,

oleum.

Armstrong follows a basic process for creating linoleum: Linseed oil and resins are combined to create linoleum cement. The cement is then added to the limestone, cork, wood powder and mineral pigments. This mixture is then rolled out onto a jute backing. It is subsequently cured for 14 to 21 days, after which factory finishes are applied.

Why we should recycle linoleum

Linoleum floors will last anywhere between 25 to 40 years, according to

Green Floors. Once your linoleum floor has come to the end of its life, you can compost it, take it to a waste-to-energy incinerator or take it to a building supply recycler for reuse.

- Linoleum can be composted because it naturally decomposes. According to Green Floors, it is fully biodegradable and does not release harmful substances or gases such as chlorine and dioxins. According to the Pharos Project, there are some pilot projects in the country that collect linoleum for composting.

- When burned in a waste-to-energy incinerating facility, linoleum products produce a residual caloric value comparable to that of coal, which means that you can produce about as much energy burning linoleum as you can by burning coal. Furthermore, the production of linoleum is a closed-loop system. This means that the energy obtained from incinerating linoleum is roughly equivalent to the energy it takes to produce it.

- The manufacturing of linoleum is extremely efficient, and any scraps that are produced are fed right back into the manufacturing process. Post-consumer linoleum products can be taken to building supply recycling centers to be resold. Reusing old linoleum flooring for various home projects or crafts is a fun way to dispose of linoleum in an environmentally responsible way.

What to look out for

A lot of people mistake vinyl flooring for linoleum. As mentioned above, linoleum is made from all-natural materials, and that is why it is compostable, fully biodegradable and safe to incinerate. Vinyl flooring, on the other hand, is a synthetic product made of chlorinated petrochemicals, according to

FloorTalk. Vinyl is not biodegradable and will release harmful toxins when incinerated. So, make sure you know whether the resilient flooring you want to dispose of is vinyl or linoleum!

Another thing to look out for is asbestos. Linoleum itself does not contain asbestos, but the adhesive used to glue it down might. If you suspect your linoleum flooring was glued down using an asbestos-containing adhesive, get it tested. If the adhesive is found to contain asbestos, have the flooring professionally removed and cleaned of adhesive before composting it or dropping it off for incineration.

Linoleum recycling regulations

Regulations associated with recycling linoleum flooring pertain mostly to the possibility of any adhesive used that might contain asbestos. There are special regulations for removing asbestos-containing materials, and it is best to have a professional remove linoleum flooring glued down with asbestos-containing adhesive.

Find the nearest linoleum recycler here.